Microbial Field Test Kit

Peter Maher – The Man Behind Liquid Intelligence

Instant Phone Advice You can call Peter now on 1800 441 163 or 02 8188 2060 (7am to 7pm seven days a week – including public holidays – except Christmas Day) for a chat about product and application information or to simply purchase Liquid Intelligence.

For Instant Phone Advice |

“How You Can Detect Algae, Bacteria, Yeast And Mould Contamination In Your Diesel Fuel”

Simply Using The Liquid Intelligence 205 Microbial Field Test KitIt Really Does Do Exactly What It Says

|

If you have biologically contaminated diesel fuel (or think you might have) then you are in the right place.

Contamination is:

- Costly

- Unproductive

- A Nuisance.

|

Diesel Bug Test Kits Whiteboard Video Explanation

|

Most Diesel Engine Failures Originate In The Fuel TankWhen water is present and the environment hits the right temperature range… dormant algae, fungi, yeast and bacteria can rapidly grow in the area of fuel/water interface at the bottom of the diesel fuel tank. Microscopic in size…. a single cell, can grow to a biomass of kilograms in just 12 hours. Symptoms of contamination can range from…. clogged and slimy filters…dark, hazy fuel…..sludge build up in tanks….excess smoke and foul odours. Eventually microbial contamination can clog fuel lines and stop engines….often with critical and expensive consequences to the fuel delivery system. Fuel tanks and lines may have to be removed and steam cleaned… fuel pump and injectors can also become clogged and may also need to be serviced… this can cost thousands of dollars.

|

Liquid Intelligence Microbial Field Test Kits Are Recommended For:

How Does The Test Kit Work?The test is easy to use and effective:

|

|

|

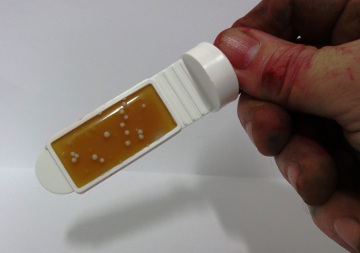

Small BottleThe kit comes in a small (approx 6 inch) plastic container. This incubator-like quality allows the bugs to grow faster when testing. |

|

Remove SlideSimply remove the slide from the test kit… with fingers touching the handle only. |

|

Dip SlideDip the slide into the diesel fuel sample for ten seconds |

|

Check In Twenty Four HoursAnd after twenty four hours the slide will detect any contamination in a diesel fuel tank. Yeast appears as low round white or grey discs |

|

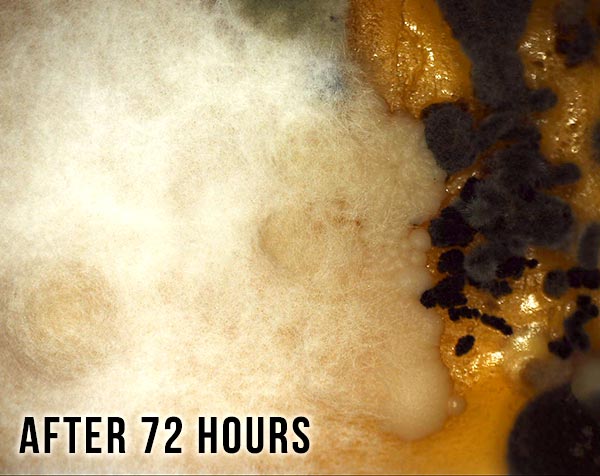

Mould appears as furry colonies |

|

Bacteria appears as red dots |

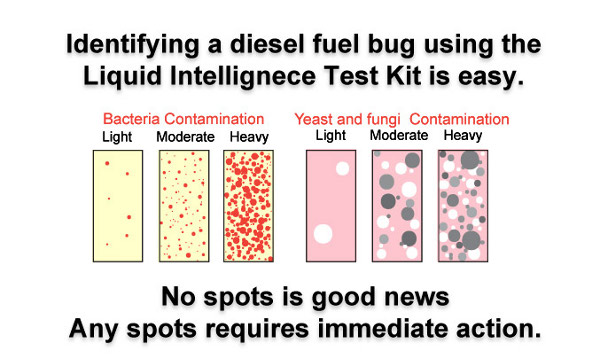

How To Interpret The Results

- Compare the slide surface against the comparison charts printed on the side of the black storage container.

- Any reaction requires immediate action.

- Bacteria and fungi will form insoluble particulate matter that can clog fuel filters, resulting in fuel starving and engine stoppage. They can also corrode metal surfaces, including storage tanks and pumps, and will form organic acids that contribute to fuel instability.

- Liquid Intelligence has a range of broad spectrum biocide treatments for killing algae and bacteria in diesel fuels.

Microbial Field Test Instructions

|

|

||||||||||||

|

||||||||||||

How Did Your Biological Contamination Happen?

|

|

|

Twenty SpeciesThere are known to be over twenty species of fuel bugs that can contaminate a diesel fuel storage tank. |

|

Doubling Every Twenty MinutesOnce in a fuel supply they can double their numbers every twenty minutes and one single spore can produce over 260,000 cloned descendants in six hours |

|

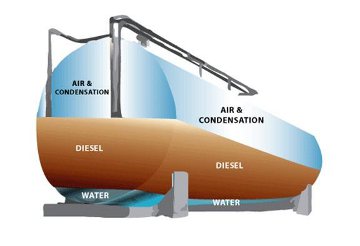

First It Grows At The Diesel/Water Interface.The fuel bug grows in the diesel/water interface at the bottom of the fuel tank |

|

Now Its In Your Engine.The contamination can be drawn into the engine… quickly clogging fuel filters… eventually leading to engine breakdown. Now it can become expensive. |

How Do You Get The Diesel Bug (Algae, Bacteria, Yeast and Fungi)?

Diesel Bug (Bacteria Contamination of Diesel)

Bacteria in diesel is a well known problem to anyone who works with diesel engines, so what is this bug and why does it contaminate diesel?

Diesel is an organic fuel so it provides an ideal environment for microscopic fungi, yeast and bacteria to feed and grow.

This environment provides:

- Dissolved water for germination

- Carbon for food

- Oxygen and sulphur for respiration

- Trace elements for growth and propagation.

As many as twenty varieties of bacteria are responsible for the majority of problems with diesel engines and their performance. There are many differing types of bacteria which can infect systems and form bio-films on steel surfaces. Accelerated corrosion can also occur wherever the bio-film settles, usually in pits or crevices. Unlike general corrosion, it is an attack on a very specific area.

It is very difficult to determine when a system is first contaminated, but once contaminated diesel enters the fuel system, it is very difficult to eradicate.

Diesel bug can originate from the air or moisture, or during tank filling and/or expansion and contraction of storage tanks, the bacteria cover themselves in a protective film (slime) to protect against biocides and can lie dormant in the minute crevices of the metal, rubber and polyurethane coatings of the fuel tanks and fuel systems.

Then, when water is present and the environment hits the right temperature range, they begin reproduction in the area of fuel/water interface.

Microscopic in size, they can develop into a mat easily visible to the naked eye very rapidly. A single cell, weighing only one millionth of a gram can grow to a biomass of 10 kilograms in just 12 hours, resulting in a biomass several centimetres thick across the fuel/water interface.

Each species has its own characteristics:And unfortunately…All of these can and do cause damage to the fuel system. BACTERIABacteria utilise hydrocarbons and reproduce asexually by binary fission; swelling in size as they feed, they then separate into two cells. In this way, microbes double their numbers every 20 minutes, one spore converting to 262,144 in 6 hours. SULPHATE REDUCING BACTERIA (SRB)SRB’s are a specific group of bacteria utilizing simple carbon, not hydrocarbons, and require the activity of other microbes in a consortium. Aerobic (in the presence of oxygen) or anaerobic (without oxygen) bacteria have a combined effect. The aerobic bacteria (sulphate oxidizing) create a film to consume the oxygen first. This allows the anaerobic (sulphate reducing) bacteria to thrive. IRON REDUCING BACTERIAThese also contribute to corrosion, eating steel and reducing ferrite to an oxide through a chemical reaction. YEASTSYeasts prefer acidic environments, such as produced by SRB’s. They bud on the parent cell, eventually separating. Reproduction takes several hours. FUNGUSFungi grow in the form of branched hypha (a part of the vegetative portion of a fungus that resembles threads), a few microns in diameter, forming thick, tough, intertwined mycelia mats at fuel/water interfaces. |

Indeed If You Have Fungal Contamination Of Diesel Fuel On Your Boat… Here’s How You Can Deal With It.Of all the users of diesel fuel the operators of boats are the most likely to encounter problems with fungus and bacteria for the following reasons:- Boats operate in a wet environment and it is not always possible stop water seeping into fuel tanks. The fuel tanks on boats are designed to fit into restricted or unusually shaped areas to make the best possible use of available space. This can mean that they can be difficult to drain and often have areas where pools of water can collect and sit undisturbed. The fuel tanks contain baffles to stop the fuel sloshing about. The baffles can trap free water in small pockets. In warmer climates boats operate in areas with high humidity. Water in the air enters the boat tanks through the breather and condenses inside the tanks. Where water is present in pockets in the fuel tanks it will provide a site for fungus and bacteria to grow. Often the fungus or bacteria will develop for a long time without causing any problems until one day they become disturbed and stirred up into the fuel. This will be noticed when filters start blocking with a black slime which is the dead matter from the fungus and bacteria. The fungus can be stirred up by :- Vigorous movement due to a storm, etc. The fungus population reaches a size at which it grows out of its sheltered corner and spreads into the rest of the fuel. The natural life cycle of the fungus reaches a point at which dieback occurs and the dead matter starts floating in the fuel. Natural surfactants produced by the fungus cause water and dirt to be suspended in the fuel and the fuel becomes hazy. PREVENTION On land the normal prevention of fungal problems is to regularly drain any water in which the fungus can grow. This may not be possible in some boats because the fuel tank shape does not provide a common draining point for all water pockets. An alternative is to consider a regular dosage of Liquid Intelligence 201 Diesel Fuel Bacteria & Fungi Biocide Treatment. The treat rate for a maintenance dose is 1 litre to 2000 litres and to kill a contamination the treat rate is 1 litre to 1000 litres. Tanks treated with a dose of the biocide at every load will stop the fungus growing, regular maintenance should be carried out to remove the water. TREATMENT Should a tank become over infested with fungus then filters will start blocking with a black slimy deposit and the fuel may be hazy with water and dirt suspended in it. In such cases the biocide should be added to the fuel tank and then the fuel in the tank should be circulated to ensure that the biocide spreads throughout the fuel. Following treatment, the water and dead fungus will drop to the bottom of the tank. It should then be drained off or sucked out with a hose, otherwise it will sit on the bottom until becoming stirred up in rough water and again block filters. Treatment should continue for a few loads until filter operation has returned to normal. |

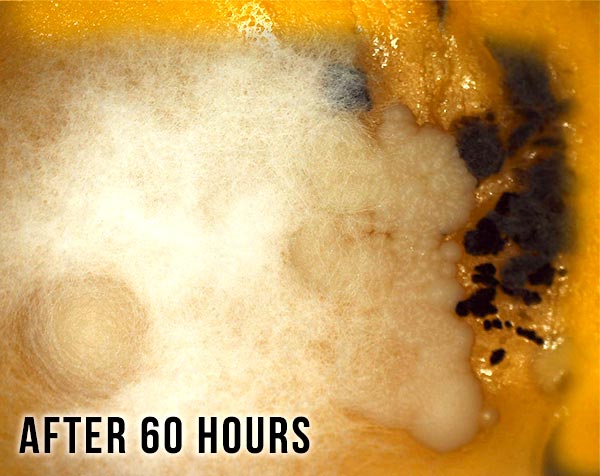

The Robert Williams Case Study

This is an example of a Liquid Intelligence Microbial Field Test Kit agar dip slide that has detected bacteria, yeast and fungi in a diesel fuel sample. The sample was sent to us by a Robert Williams a property manager from north west NSW. He had become concerned that 6000 litres of diesel in his storage tank, was slowly becoming darker. He first noticed this happening soon after taking a delivery from a local bulk fuel supplier. He suspected that the recent delivery was somehow contaminated. We tested the diesel sample for him using our Microbial Field Test Kit and took these images under a microscope at 12 hour intervals. The fuel sample was taken from a drain tap at the very bottom of the tank and the time laps images indicate that it was contaminated with various strains of microorganisms. Rob used our Liquid Intelligence 201 Diesel Fuel Biocide to eradicate this infestation before it became a problem. He also purchased some more dip slides so he could check that the bacterial infection was completely eliminated after he had used the Liquid Intelligence 201. We also suggested that Rob add a dose of Liquid Intelligence 201 Diesel Fuel Biocide into all the equipment that had been filled from the infected tank to insure that the bug did not spread, as a precautionary safeguard. Rob’s problem is very common, the most likely scenario was that the bacterial contamination was already festering in water at the bottom of his storage tank. And it may have been there undisturbed and undetected for some time. This can be the case when the draw off tap is well above the bottom of the bulk storage tank. And the recent delivery of fuel being pumped into the tank could have stirred up the bottom and dispersed the microorganisms and fouling the diesel. When water is present from a build-up of condensation dormant algae, fungi, yeast and bacteria can rapidly grow in the area of fuel/water interface at the bottom of the diesel fuel tank. Even though microscopic in size, a single cell, can grow to a biomass of kilograms in days or weeks if left untreated. Symptoms of contamination can range from…. clogged and slimy fuel filters, dark or hazy fuel, sludge build up in the bottom of fuel tanks and excessive combustion smoke with foul odours. Eventually microbial contamination can clog fuel lines and stop engines….often with critical and expensive consequences to the fuel delivery system. |

|

||||||||||||

Peter Maher’s Minchinbury Wharehouse Office Webcam

|

Webcam Minchinbury Office Webcam: Call Peter, he is in the office today. In our Sydney office it is now: |

|

Peter Maher – The Man Behind Liquid Intelligence

You can call Peter now on 1800 441 163 or 02 8188 2060 (7am to 7pm 7 seven days a week – including public holidays – except Christmas Day) for a chat about product and application information or to simply purchase Liquid Intelligence.

|

Send Me An Email:

If you would like to know more about the technical aspects of these products and how it relates to your particular vehicle... please send me an email and I will usually respond on the same business day.... Peter Maher.

|

|

Written by Peter Maher

Peter Maher, has been in the chemical industry since he was 18. So that’s more than 40 years he’s been blending, manufacturing and formulating functional automotive and industrial fluids. |

Click On The Product Or Issue That Interests You From The Grid Below

Liquid Intelligence 126 Silicone Brake Fluid Dot 5

|

Liquid Intelligence 115 Super Waterless Coolant – Guaranteed No Overheating

|

Liquid Intelligence 115 Motorcycle Super Waterless Coolant – Guaranteed No Overheating

|

Liquid Intelligence 201 Diesel Fuel Bacteria & Fungi Biocide

|

Liquid Intelligence Microbial Field Test kit

|

Liquid Intelligence 204 Diesel Moisture Absorbent

|

Liquid Intelligence 207 Diesel Fuel Cetane Booster

|

Liquid Intelligence 218 Diesel Purge And Restore Fuel System Cleaner Super Concentrated Formula Improves Performance & Power In Just One Treatment

|

Liquid Intelligence 219 Super Concentrate Engine Flushing Additive

|

Liquid Intelligence 224 Lifter-Free Engine Oil Additive Stops Lifter Clacking. Guaranteed.

|

Liquid Intelligence 229 Diesel Fuel Pump Seal Leak Fix

|

Liquid Intelligence 230 Stop Oil Leak Seal Expander

|

Liquid Intelligence 230 PLUS – Stop Oil Leaks – Gear Oil Grade

|

Liquid Intelligence 235 Hydraulic Stop Leak Seal Expander

|

Liquid Intelligence 236 Anti-Shudder Additive for Auto Transmissions

|

Liquid Intelligence 237 ZDDP Engine Oil Additive

|

Liquid Intelligence 238 Cooling Systems Oil Sludge Remover

|

Liquid Intelligence 239 Engine Cooling System Cleaning Kit

|

Liquid Intelligence 240 Organic Rust Remover is the fastest way to totally remove rust from metal without damaging the original piece.

|

Liquid Intelligence 243 Radiator Stop Leak Repair Kit Fixes Leaks In Cooling Systems And Radiators Guaranteed.

|

Liquid Intelligence 245 Blown Head Gasket Repair

|

Liquid Intelligence 245 Blown Head Gasket Repair with Sealing Aid Optimizer.

|

Liquid Intelligence 246 Blown Head Gasket Test Kit |

Liquid Intelligence 318 Racing Brake Fluid

|

Liquid Intelligence 500 Latest Generation Technology, Long Life Ready To Use Green Universal Antifreeze Anti-Boil Coolant

|

Liquid Intelligence 600 Vintage & Veteran Super Soluble Oil Radiator Coolant

|

Liquid Intelligence 719 Car Air Conditioner Sanitizer and Deodorizer

|

Liquid Intelligence products are the BEST OF THE BEST. They have the highest degree of efficiency, activity and functionality, compared to any similar retail grade product.

Liquid Intelligence products are the BEST OF THE BEST. They have the highest degree of efficiency, activity and functionality, compared to any similar retail grade product. Unbeatable personal technical advice and support: “You Are Not Alone… When you ring us “We Are Here To Help You” get that problem sorted.

Unbeatable personal technical advice and support: “You Are Not Alone… When you ring us “We Are Here To Help You” get that problem sorted. Technical support staff with more than 40 years experience in the industry.

Technical support staff with more than 40 years experience in the industry. Made in Australia by an Australian business and exported around the world.

Made in Australia by an Australian business and exported around the world.

Applies to most of our popular products where you see this icon in the "add to cart" box

Applies to most of our popular products where you see this icon in the "add to cart" box